Georgia Tech Team Chemistry is Key to Success at ASME Hackathon

August 26, 2021

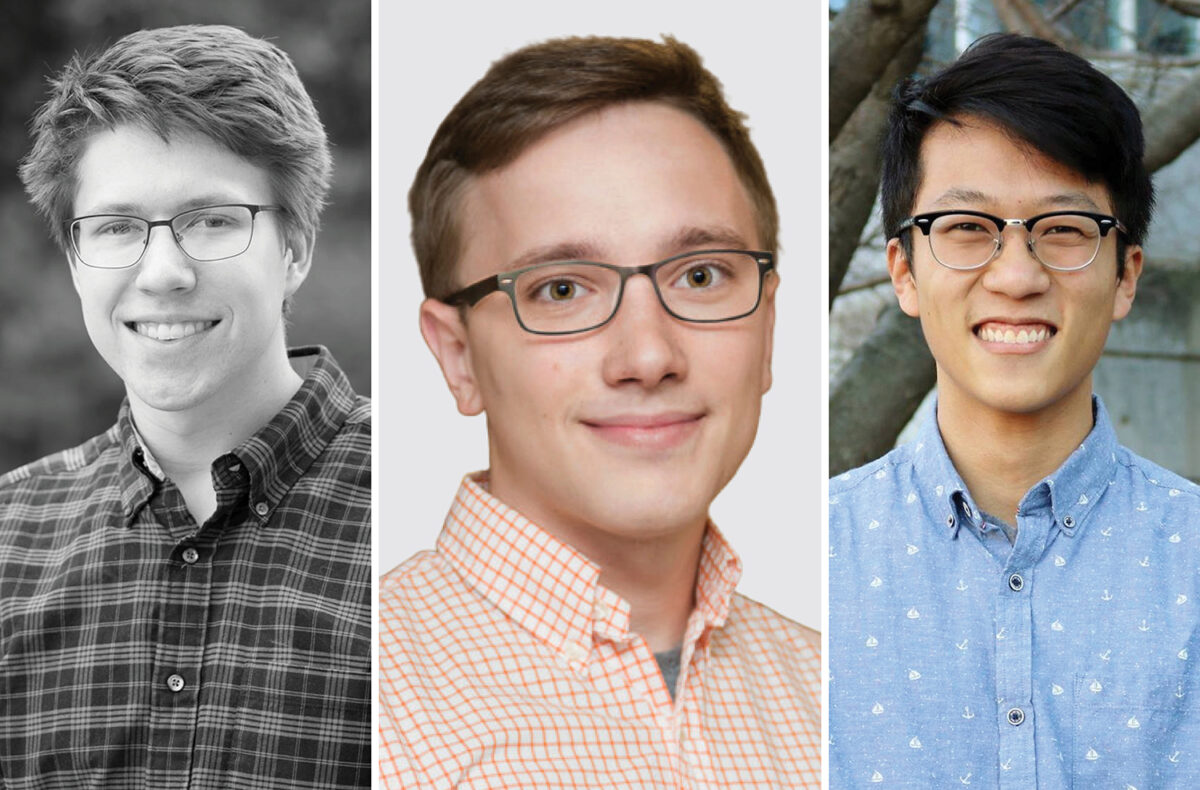

A team from the Georgia Institute of Technology recently won the 2021 ASME-CIE Hackathon, a 24-hour competition that took place virtually August 14-15. Mechanical engineering Ph.D. student Nathan DeVol and recent graduates Patrick Jung (MS ME ’21) and Lance Lu (BS ME ’18, MS ME ’20) successfully tackled two problems that explored the power of data and cybersecurity for mechanical engineering. They earned first place in both competitions.

DeVol, Jung and Lu used the collaborative skills they developed as members of the Enhanced Preparation for Intelligent Cybermanufacturing Systems (EPICS) team to give them an edge over their competition. EPICS consists of graduate and undergraduate students and faculty from Georgia Tech involved in advanced hybrid additive manufacturing research, industrial internet of things technologies (IIOT) and broad makerspace technology deployments.

“This was my first hackathon and it was a really fun and rewarding experience, but being able to work with fellow EPICS lab mates was the best part,” said Clemson, SC native DeVol, who was recruited to join the EPICS team by George W. Woodruff School of Mechanical Engineering professor and EPICS faculty advisor Thomas Kurfess.

Christopher Saldana, who has served as a co-advisor to the three team members alongside Katherine Fu, encouraged Jung to enter the hackathon. Jung, a native of Knoxville, TN, was interested in solving a fun puzzle so he recruited DeVol and Lu to join the team.

“Patrick reached out to me with the problem statement. Additive metal manufacturing is definitely an exciting area of research that I don't have too much familiarity with so I thought it would be a good learning opportunity,” said Lu, who is from Toledo, OH. “Working and messing around with my friends is a definite plus, too.”

The first hackathon problem pushed the three team members to assess the robustness of security strategies to hide design information in digital manufacturing and stimulate the critical thinking process. They were given an STL file of a dice and had to find clues that were hidden in the file to determine which side corresponded to which number.

The team knew from experience that they would need to sprint at the beginning to test some ideas before settling on a solution.

“I think with our research and programming backgrounds, we had a better idea of how feasible some ideas were to implement in a 24 hour time period,” said Lu. “We agreed that throwing computing power at a problem would cost too much time if it didn't end up working so we explored several ‘lower budget’ methods.”

For the second problem the team focused on identifying the locations of dropped frames in a stream of images from an additive manufacturing melt pool camera. For Jung, studying additive manufacturing during his time at Tech gave him context to the problem and helped him structure possible solutions. However, the team’s initial approach didn’t lead them anywhere. They had to pivot near the end which was their biggest challenge.

“We were racing the clock at the end and submitted our work minutes before the deadline,” said DeVol.

For their efforts the Georgia Tech team earned $2,600 in prize money, and comes away with a better understanding of the problems being faced in research and academia as they relate to additive and digital manufacturing, and the inspiration to compete in future hackathons.

“Hearing our names called twice at the awards ceremony for first place awards was truly joyous,” said DeVol. “I don’t think we would have been able to do this if our team didn’t already have some team chemistry from past years as lab mates.”

Until the next competition, DeVol will continue his research as a Ph.D. student at Georgia Tech; Jung will work as a Mechanical Design Engineer with Advance Medical Designs in Marietta, working on product development of new devices to assist with surgical procedures; and Lu will work as a Systems Engineer with Aging Aircraft Solutions in Atlanta, working on digital manufacturing solutions and the transitioning of legacy systems to digital.

And for any students thinking of entering a hackathon, the team has a few words of advice:

“It is definitely worth a try. They are low-risk, high-reward challenges where you learn, compete and have fun with your friends,” said Jung.

“I say go for it!” said Lu. “You can learn a lot and meet a lot of experts/mentors doing exciting work. You can exercise a lot of creativity towards solving real challenges.”