The Friday Five with Capstone Design Team Sugar and Slice

December 2, 2022

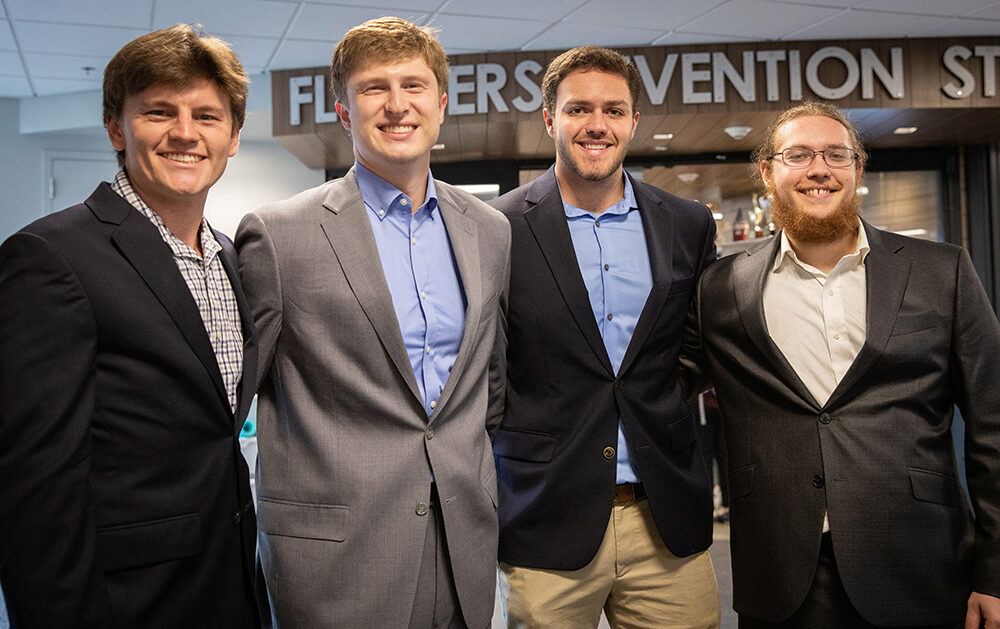

Get to know mechanical engineering team Sugar and Slice who will showcase their project, “Fruit & Vegetable Slicer,” at the fall 2022 Capstone Design Expo.

1. Can you tell us about your team and project?

Our Team is made up of four mechanical engineering majors:

- Zachary Bellis from Marietta, Georgia

- Mason Randall from Warner Robins, Georgia

- Nicholas Rokos from Norwood, North Carolina

- Nicholas Simon-Brecke from Atlanta, Georgia

We are developing a manual fruit and vegetable slicer for Cameroonian refugee farmers that will be made from local materials using local tools. Large amounts of excess fruit grown by Cameroonian farmers consistently go to waste because there is no efficient, reliable method of preserving fruit. We will build on a solar fruit dryer that a previous Capstone team developed to create a fast and safe slicing tool to appropriately slice fruit so that they can be dried effectively. As more fruit can be produced and preserved, more mouths can be fed, more fruit can be sold, and farmers' economic livelihood will increase. Additionally, we will produce and send an instructional video to the Cameroonian engineers to show how to build the slicer, which will allow many farmers to have access to this tool.

2. What was your team’s design process, how do you go about separating different tasks, and what are some of the biggest challenges you have faced?

Our team approached the problem with an iterative design process, first outlining the overall goals, examining the customer requirements, defining the engineering requirements, and tossing out many different potential solutions. Some initial calculations and models were developed to narrow down initial prototypes, and, after the selection of a prototype, physical construction began.

The team broke down roles at the beginning of the project by simply talking about our strengths and what we wanted to get out of the project this semester. Each role has certain tasks that the person will do, and we do our best to stick to those tasks, helping each other as needed. This has helped the team make consistent progress while ensuring that the work done is correct and usable.

The biggest challenges in the design process relate to the limitations of the manufacturing processes in South Cameroon. The proposed solution will primarily be made of wood found from local lumber yards, and even simple components like fasteners can be difficult to acquire. Although the product will be created by technicians in towns for use by farmers in rural areas, the technicians will not have access to the overly sophisticated woodworking shops that we have become accustomed to. This means that not only will our design need to solve the problem with minimal material requirements, but we will also have to ensure that the system and its components can be manufactured with the tooling that they have available.

3. Have there been any highlights while working on your project?

One of the best highlights for our team so far has been speaking with local farmers in Cameroon and Nigeria that will benefit from our project. While contacting them can be a logistical challenge at times, their advice has shaped the direction of our project. It has been so helpful to have their input to make sure that our solution makes their lives easier, and it really makes our impact feel more tangible.

4. Can you tell us about your experience working with a sponsor?

The interesting part of our project is that we aren’t working with a particularly large corporation. Amba Farmers Voice is a nonprofit organization focused on providing agricultural education to farmers and war refugees in Africa. It has been great to be providing aid alongside an organization with such a noble mission. While there are teams working with multimillion-dollar organizations, our project’s number one goal is to improve the lives of those living in third-world countries, and we all have found it easy to be inspired to do the best job possible knowing that our work will truly be making a difference.

5. What team attributes have contributed the most to your success?

Strong communication has been one of the aspects that has made our team successful. When we're all on the same page, it makes every step of the process easier, from report writing to designing, to prototyping. We work well together because we can regularly communicate our ideas and quickly start building on them. Shared accountability is another aspect that has contributed to the success of the team. Each team member has a strong understanding of what is expected of them, and there is a mutual desire to create the best project possible.

The fall 2022 Georgia Tech Capstone Design Expo will take place on Monday, December 5, from 4-8 p.m. at McCamish Pavilion on the Georgia Tech Campus. At the Expo, over 600 seniors from various disciplines of engineering and industrial design will showcase their innovative projects designed and built during their Senior/Capstone Design course. Register to attend.